The Power of Process: The Role of the System Architect

Watch Now!

How Better Process Design Prevents Rework, Waste, and Firefighting

Webinar Description

Many organizations invest heavily in Lean, continuous improvement, and operational excellence—yet still struggle with recurring rework, stalled initiatives, and “fix it later” problem-solving.

The root issue often isn’t execution. It’s how processes are designed in the first place.

In this on-demand KaiNexus webinar, Eric Effington explores why organizations fall into costly cycles of rework and how the often-overlooked role of the system architect can help prevent those problems before they start.

Drawing on more than 35 years of experience across automotive, aerospace, healthcare, energy, and logistics, Eric introduces a practical framework for designing processes that work—without sacrificing learning, flexibility, or people engagement.

This session goes beyond tools to focus on how organizations design systems, how leadership behaviors shape outcomes, and how Lean thinking can be applied earlier to reduce downstream pain.

View all previous KaiNexus Continuous Improvement Webinars

What You’ll Learn

-

Why many improvement efforts unintentionally create rework

-

How upstream process design impacts downstream performance

-

The Six-Concept (Six “Con”) model for process development

-

What a system architect does—and why the role matters

-

How to balance stability, learning, and flexibility in process design

-

Practical lessons for getting started without overcomplicating things

Key Insights

-

Fixing problems later is far more expensive than designing processes well upfront

-

Process development should be treated as a system—not a one-time project

-

Learning must be intentionally built into how new processes are created

-

Leadership behaviors can either enable or undermine sustainable process design

-

The system architect acts as a bridge between strategy, execution, and learning

Who This Webinar Is For

This webinar is especially valuable for:

-

Continuous improvement, Lean, and operational excellence leaders

-

Executives and managers responsible for large-scale change

-

Value stream managers and process owners

-

CI practitioners frustrated by recurring rework

-

Organizations designing new services, clinics, lines, or workflows

About the Presenter:

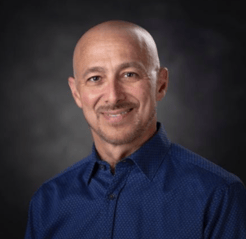

Eric Ethington

Eric Ethington

Eric Ethington has a pragmatic approach for lean with over 35 years of work experience at Delphi, Textron, and LeanShift. He has been fortunate to learn about the science and methods of improvement from some of the best teachers available while working with highly capable teams in industries such as automotive, aerospace, defense, healthcare, medical devices, energy, and logistics.

Eric holds a Bachelor of Science degree in Industrial Engineering from Kettering University (formerly GMI) and an MBA in Operations from the University of Michigan, Flint campus. He earned a Six Sigma Design Black Belt while working at Textron. He serves on the Board of Directors at Goodwill Industries of Mid-Michigan as well as the Alumni Advisory Board for the Industrial and Manufacturing Engineering department at Kettering University. Most recently, Eric has co-authored the book, The Power of Process, A Story of Innovative Lean Process Development with his long-time colleague and collaborator, Matt Zayko.